Production Line Printed Circuit Board Assembly Process Flow

PCB Assembly Process or PCBA Process Flowchart Starts with Bare PCB (Printed Circuit Board). Here I explain PCB Assembly Process with PCBA Flow Chart.

PCB Assembly Process or PCBA Process Starts with a Bare PCB (Printed Circuit Board). Here I will explain the PCB Assembly Process with the help of a PCBA Flow Chart. This PCB Assembly Flowchart is same for all types of PCBs.

PCB Assembly Process (Selective Soldering)

PCB Materials

PCB Assembly Process (PCBA Process) starts with a bare ready to assembly PCB. So, before we understand the Assembly Process in Electronics, it is important to understand different PCB materials used to make the base of a Printed Circuit Board.

PCB Materials

A Printed Circuit Board (PCB) is can made of different heat resistant insulating materials. This base material can be Resin Based, Fiberglass Based, Epoxy Glass, Metal Board, Flame retardant (UL94-VO, UL94-V1), heat resistant plastic, kepton (For Flexible or Flex PCB) etc. Conductive copper tracks are printed or etched onto this con-conductive base substrate. The board is then coated with Green Mask and Silkscreen. Active and Passive Electronic components are then soldered onto this board either by Thru-Hole soldering Technology or SMT Technology or Hand Soldering, making it a Printed Circuit Board Assembly (PCBA).

Learn all about: PCB Materials

Types of PCB

Next to understand is different types of PCB. Different PCB Manufacturers design and manufacture different types of PCBs. A Printed Circuit Board can be of following Types:

1. Single Sided PCB or Single Layer PCB – These types of PCB has only one single layer of the base substrate and one single conductive (copper) layer. Electronic Components are soldered on one side only.

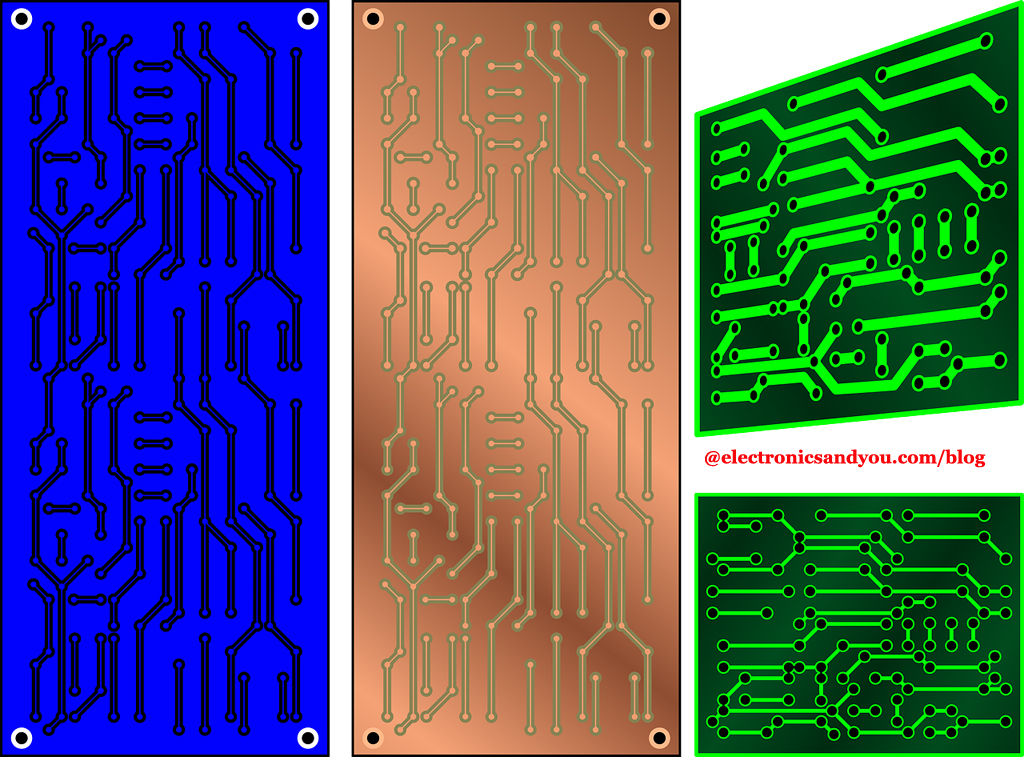

Single Sided PCB or Single Layer PCB

2. Double Sided PCB or Double Layer PCB – These types of PCB have one single layer of the base substrate but conductive (copper) layer and electronic components on both sides of the substrate. Green mask and Silkscreen is applied on both sides of the board.

Double Sided PCB or Double Layer PCB

3. Multilayer PCB – These Types of PCB have more than 2 layers. A Double-Sided PCB has two conductive layers on top and bottom of the PCB substrate. A Multilayer PCB must have a minimum of 3 conductive layers of conductive material or copper layer. All the layers are interconnected with copper plated holes. The layers can be 4, 6, 8…upto 40 layers.

Multilayer PCB (Printed Circuit Board)

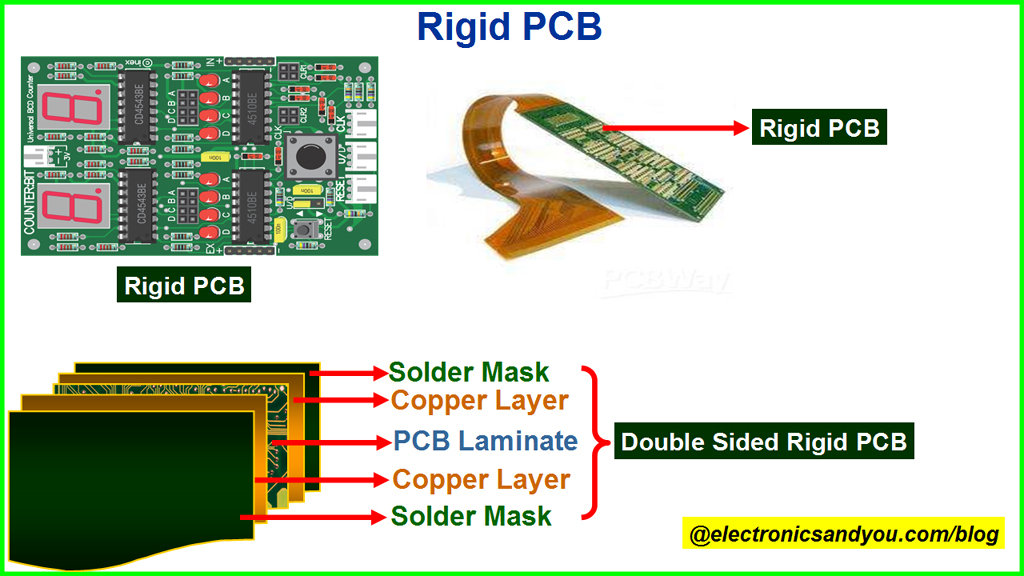

4. Rigid Printed Circuit Board – These types of PCB are Solid, inflexible Printed Circuit Board.It cannot be bend or forced out of shape. It is not flexible. A Rigid PWB can be Single Sided, Double Sided or Multilayer.

Rigid Printed Circuit Board

5. Flex PCB or Flexible Printed Circuit Board – As the name suggests, these types of PCB are flexible and can be folded. They are are not hard as Rigid PCB. Substrate of a flexible board is made of flexible plastic (thin insulating polymer film), polyimide or a similar polymer or Kapton. Conductive copper circuit is printed on this substrate and a protection coating of thin polymer is applied to protect the circuits.

Flex PCB or Flexible Printed Circuit Board

6. Rigid Flex Printed Circuit Board – These types of PCB are hybrid combination of a Rigid PCB and a Flex PCB. Both rigid and flexible PCB substrates that are laminated together to form a single circuit board. Double sided or multilayer Rigid Flex Circuit Boards are interconnected by plated through holes (PTH). These types of PCBs are commonly found in Mobile Phone, Smartphone, Tablets, Laptop and Computer and other Foldable Electronic Gadgets. Now more and more electronic companies in the world are using these Rigid-Flex PCBs.

Rigid Flex Printed Circuit Board

PCB Assembly Process Flow Cart

Have a Look at the following PCB Assembly Process Flowchart to understand the assembly process in electronics.

PCB Assembly Process Flowchart

PCB Assembly Process Flowchart Explained – Step by Step

Let us know discuss the flowchart in detail to understand and make clear the PCB assembly process.

- The process starts with ready to assemble bare PCB.

- If there is SMD Component on at least one side of the board then following steps are followed: Solder Paste Screen Printing -> Pick and Place SMD Components -> Reflow Soldering.

- If there is SMD components on other side of the board then SMT Adhesive is applied and again all steps of above step number 2 are repeated.

- If there is no SMD component on the other side then SMT Inspection is done with X-Ray Inspection Machine.

- Now, if there are through-hole components then wave soldering is needed.

- If there are no thru-hole components the it is checked if hand soldering is needed or not.

- If hand soldering is needed then it is done and the board goes for final inspection. If hand soldering is not needed the the board directly goes to the final inspection.

- If there are no SMD components on either side of the board, then there must be through-hole components to assemble. This process is done by placement of through-hole components on the circuit board followed by wave soldering.

- Now it is checked if hand soldering is needed or not. If yes, then hand soldering is done and then the board goes for final inspection. If hand soldering is not needed then the board goes directly for final inspection.

After PCBA Process

During the PCB assembly process, all kinds of Solder wire, solder bar, solder paste (Leaded or Lead-Free Solder), Different Types of Flux and SMT Glue or Adhesive are used. All these impurities and flux and chemical residue must be cleaned. If they are not cleaned then after some time they start to smell and feel sticky and becomes acidic. This can damage solder joints over time.

Hence it is very important to clean the Board. This is done by using PCB Cleaning Machine and Deionized Water. Sometimes specially formulated PCB cleaning detergents are also used for cleaning the PCBA.

After washing and cleaning, the boards are dried with compressed air and now the PCB Assembly is READY.

Video – SMT PCB Assembly Process

PCB Standards and Specifications

- MIL-PRF-31032, Performance Specification Printed Circuit Board/Printed Wiring Board

- MIL-PRF-55110, Performance Specification for Rigid Printed Circuit Board/Printed Wiring Board

- MIL-PRF-50884, Performance Specification for Flexible and Rigid-Flexible Printed Circuit Board / Printed Wiring Board

- GR-1274, Requirements for Reliability Qualification Testing of Printed Wiring Assemblies

Reflow Soldering SMT PCB Assembly Process

Related Posts:

- PCB Vs PCBA – What is the Difference

- SMT Vs Through Hole Technology – Advantages and Disadvantages

- Printed Circuit Board (PCB) for Surface Mount Technology (SMT)

- Surface Mount Soldering Guide – SMD Soldering

- Top 10 PCB Assembly Companies in USA

- PCBA Tools

- ESD Safe – Electrostatic Discharge Safety

- BGA (Ball Grid Array): Repairing and Soldering BGA

- Top 10 PCB Manufacturers in China

- RoHS Guide in Electronics: RoHS, WEEE and Lead-Free FAQ

- Soldering in Electronics

- Electronic Components Manufacturers, Suppliers and Distributors

- Basic Soldering Guide – How to Solder Electronic Components

- Pin Hole and Blow Hole Wave Soldering Defect and Remedy

- MIL-PRF-31032, Performance Specification Printed

- MIL-PRF-55110, Performance Specification for Rigid Printed Circuit Board/Printed Wiring Board

- IPC Standards for PCB Assembly

- PWB/PCB Design – Analog, RF & EMC Considerations in Printed Wiring Board Design

- PCB Design/Layout Tutorial (PDF)

- PCB Glossary of Terms

- First PCB Patent – Patent Nº 2,756,485 – Process of Assembling Electrical Circuits

- Free Online PCB Gerber File Viewer

Production Line Printed Circuit Board Assembly Process Flow

Source: http://www.electronicsandyou.com/blog/pcb-assembly-process-flow-chart-pcba-process-flowchart.html

Tidak ada komentar:

Posting Komentar